Butted Tubing

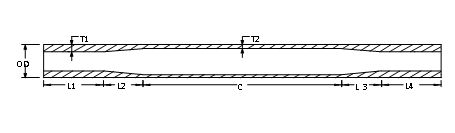

On double-butted tubes the thickness of the tubes at both ends is thicker than in the centre, so a typical double-butted tube (0.8/0.5/0.8) would have a thickness of 0.8mm at the end (1), a taper portion, then a centre section of 0.5mm, a taper portion, and a thickness of 0.8mm at the end (2).

This is used for the top and down tubes. When a lugged frame is being constructed, the seat tube would be single-butted. So at the bottom bracket end, the tube would be 0.8mm thick, there would be a taper portion, and then the 0.5mm would continue to the top of the tube, to allow the seat pillar to be inserted.

These are double-butted tubes, with different thicknesses at each end. A typical tube would be 0.9/0.6/1.2mm thick. At the 1.2mm end, we then bulge the tube so the inside diameter is 27.2, which would take a standard seat pillar. The frame builder also has the extra thickness for TIG welding.

There are several steps in manufacturing butted tubing, and the process varies depending on the method used to butt the tube, and whether the tube is seamless or welded. For steel tubing, the basic tube is either made from a pierced billet if it is a seamless tube or from a formed-and-welded sheet if it is a welded tube.

Typically, a seamless tube will be made from a billet of steel about 10 inches in diameter and 3 feet long. After heating it to over 1000 C, a hole is then pierced through the centre to form a very thick-walled tube. The wall thickness and diameter of this tube are then progressively reduced by hot rolling and cold drawing until it is sized for the butting process.

Welded tube is made from flat strip, which is formed into a tube and welded along its length. This is a straightforward way of making a tube, but care is necessary to avoid structural and cosmetic defects at the weld.

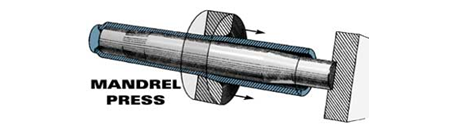

Reynolds Butting process in the UK uses a mandrel press

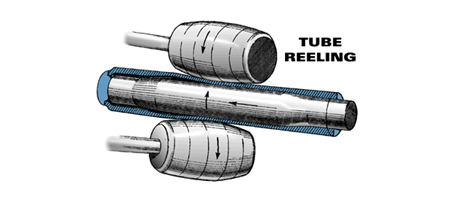

In a mandrel press, the tube is pushed through a die, sinking it down onto the mandrel. The die determines the outside diameter and the profile of the tube, while the mandrel sets the inside diameters and defines the wall-thickness profile. After this process, the mandrel is trapped inside the tube in a conventional double-butted geometry, where the end wall thickness is greater than in the middle section. The mandrel is removed after reeling the tube between angled rotating rollers, which increases the diameter while having a negligible effect on the wall thickness. Finally, the outside diameter is sized by pushing the tube once again through a die.

The processes above can also be applicable to aluminium butted tubes. Reynolds developed alternative processes for titanium mandrel butting, magnesium mandrel butting and the latest product, our Maraging 953 stainless steel. Each of these products have specific technical challenges that required innovative techniques to be used.

Over the years Reynolds have worked with frame builders to establish the ideal bend in a fork for the style of frame being built.

We have developed a slow, gradual bend for road frames, and this is bent with a 30mm offset. This is known as rake 16 x 30.

For touring frames more bend is required to absorb the rigours of long-distance riding, so a sharper bend is put into the blades, this time for 45mm. This is known as rake 15 x 45mm.

On both of these blades, builders can make minor adjustments by careful cutting to length before welding.