Monday 8th January 2024

From Nails to Bicycle Tubes: The Birth of Reynolds

On the 20th of December 1898, The Patent Butted Tube Company came into existence. The directors were Mr. Alfred John Reynolds and Mr. Alfred Milward Reynolds.

They had previously been running three nail-making factories across the West Midlands – The Crown Nail Works, The Phoenix Nail Works, and Chunk Nails. Alfred Reynolds wanted to transition into the booming cycle industry to create an innovative way of making the tubes thinner and lighter to make bicycles better performing. An ethos that continues through Reynolds to this day.

Reynolds’ first tubing factory was in New Town Row, Aston, Birmingham approximately 5 miles from where Reynolds is located today. There were 25 employees to start with and the factory had a draw bench, two butting machines, a reeler and a few other associated machines. Curiously, almost the exact same setup that is in use in 2023. They went through a period of rapid expansion – the minutes recording regular purchases of additional machinery to meet capacity.

By 1907 they had expanded into a second factory in Grove St, Smethwick.

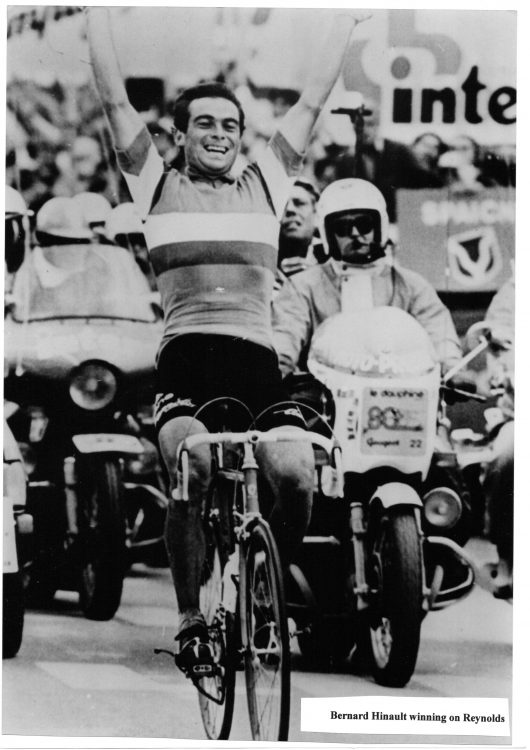

The minutes also record the ups and downs of the cycle tubing industry. The competition from upstarts in Yorkshire, industry troughs and peaks, however, it was Reynolds that would emerge as the dominant supplier of premium cycle tubing.

During the Great War, Reynolds was running flat out and expanding. The expansion of capacity was initially for military bicycles and motorcycles. In 1916 they expanded further to support the supply of parts into the revolutionary new aircraft industry. One other curious military contract was the supply of Lance Tubes for the Russian Army. The lances were inspected by Russian Generals in full military regalia. Quite a sight for the streets of Aston.

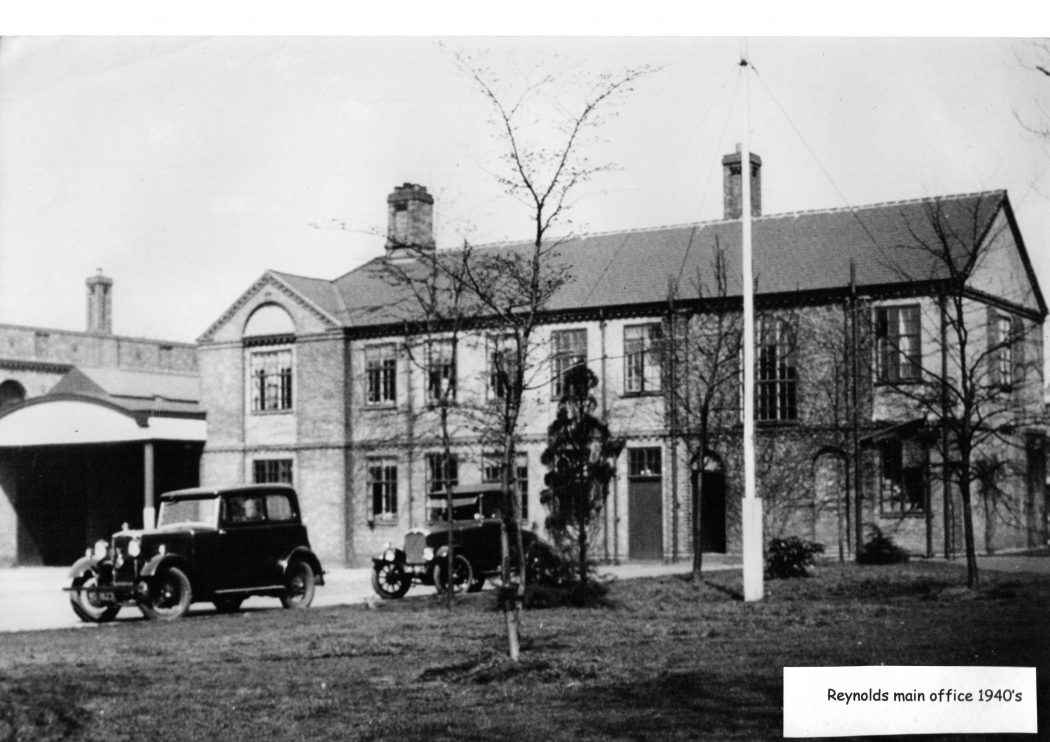

The extra capacity was urgently needed and the Ministry of Supply facilitated the purchase of the Hay Hall site that was to become Reynolds’ home for the next 80 years, although it was only completed in the summer of 1918, too late to make any significant contribution to the war effort.

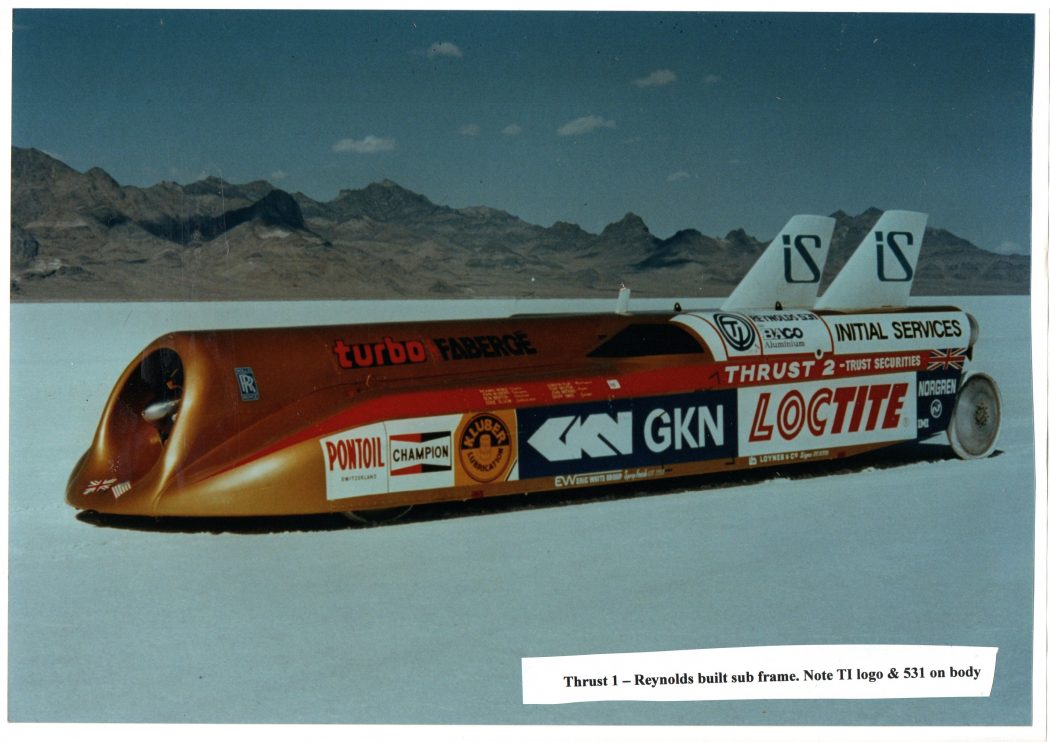

The work in the field of aeronautics was to become the inspiration for Reynolds’ post-war growth and the development of the legendary 531. Curiously it would only be in 1923 that the Patent Butted Tube Company became Reynolds Tube Co Ltd. some 25 years after the patent was awarded.

Why did Mr. Alfred John Reynolds and Mr. Alfred Milward Reynolds move from nail making to making cycle tubes? It is not recorded in the Reynolds archive what the reasons were, but an interesting theory emerges when you look into the history of nail making.

Nail making in the 19th Century had gradually moved from a craft industry into a mechanised one. But nails were still essentially a square profile, with a formed top. As a result, they were quite expensive to both make and buy. At the end of the 19th Century, an innovation from Belgium was to revolutionise the industry: making round nails from wire. This was much faster and hence much cheaper.

Mr. Alfred John Reynolds and Mr. Alfred Milward Reynolds were then faced with two options; re-tool to make wire nails, and perhaps lower profits as they were much cheaper, or continue making square nails as a niche producer and perhaps gradually go out of business. Square nails would remain a good business venture for many more years to keep shoeing the 3 million horses that were still responsible for most local travel in Britain.

The nail-making businesses continued for another 50 years, gradually shrinking from three factories to one, surviving into the 1950s. But it was cycle tubing that put the Reynolds name on the map.

Search

Categories

Archives

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- August 2023

- July 2023

- June 2023

- April 2023

- March 2023

- January 2023

- November 2022

- August 2022

- January 2022

- April 2021

- March 2021

- July 2019

- May 2019

- March 2019

- December 2018

- October 2018

- July 2018

- June 2018

- May 2018

- April 2018

- February 2018

- January 2018

- November 2017

- October 2017