Monday 11th December 2023

Reynolds 125th Anniversary – A Retrospective Look at the Last 25 Years!

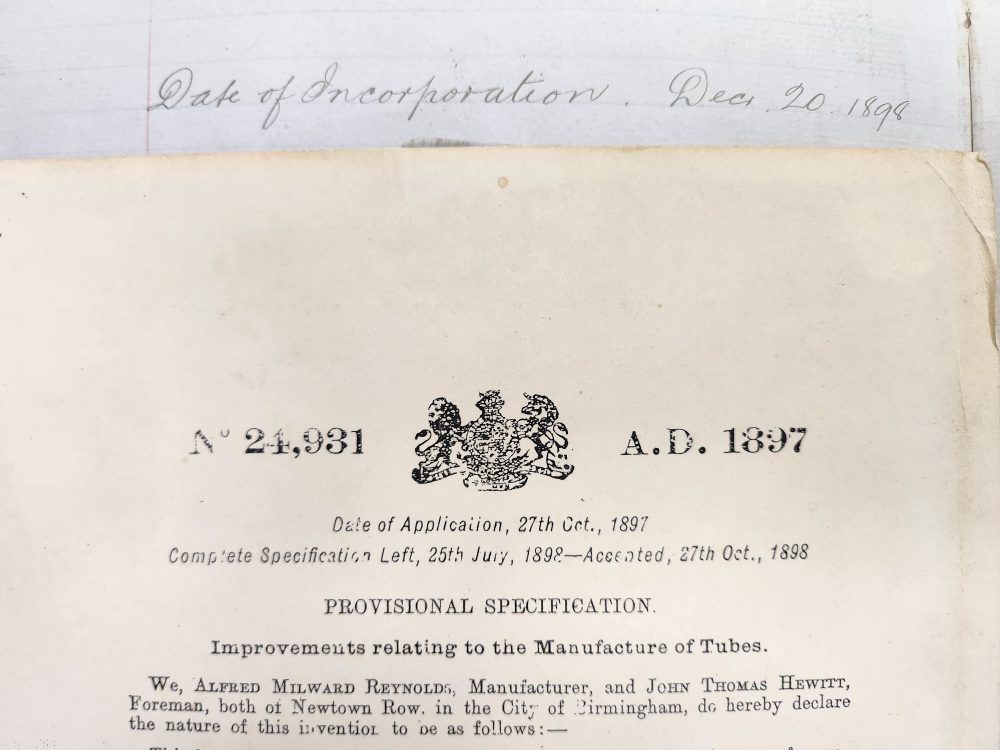

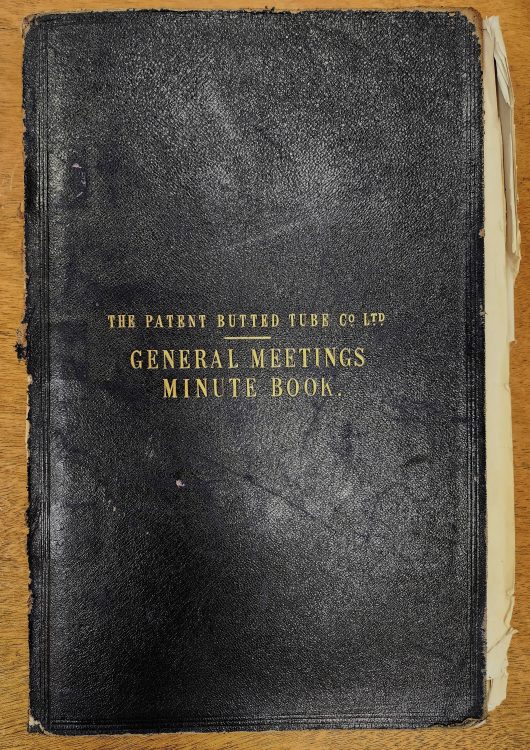

It was 125 years ago today when Alfred Milward Reynolds decided to start “The Patent Butted Tube Company “ in Birmingham on 20th December 1898.

Initially privately owned, that company became part of Ti Group PLC from 1928 to 1996, and then US-based Coyote Sports Inc. owned Reynolds until 2000. During the late 1990s, Coyote’s management focus was on the emerging carbon-fibre products, especially as their main revenue came from golf shafts.

Reynolds Composites, based in San Diego, launched the Reynolds Ouzo Pro fork with that company later being sold to Maclean-Fogg and subsequently Hayes, with their current products being carbon fibre wheelsets – this entity has no link with our UK company apart from the brand name.

Reynolds’ 100th anniversary in 1998 was celebrated under Coyote ownership. Some of our biggest customers at that time were LeMond with several 853 US-fabricated models, Gazelle who used 853 on their Tour De France bikes, and we worked with many other brands like Bob Jackson, Co-Motion, Dawes, Fuji, GT bikes, Guru, Independent Fabrication Jamis, Kona, Mercian, Pashley, Schwinn, Raleigh, Rivendell, Serotta, Waterford.

The most influential trade show was Interbike in the US, although many countries had their own bike shows. A swing from steel to aluminium frames as a competing material was underway, so Reynolds launched our X-100 aluminium-lithium alloy in 1998 as a higher-strength alternative to 6061 and 7005-based framesets. Our X-100 raw material was sourced from the US extruder that produced the Space Shuttle booster tank material but that supply chain was closed down when the programme sadly ended.

When Coyote got into financial difficulties in January 2000, the UK-based Reynolds business became privately owned and we reviewed our future product line-up. Reynolds Technology Ltd decided to focus on high-strength steel and titanium products as we had a wealth of experience in this field, specialised production equipment and did not require large volumes to be viable. Metals lent themselves to smaller volume, custom-manufactured products that can be brazed or welded around the world.

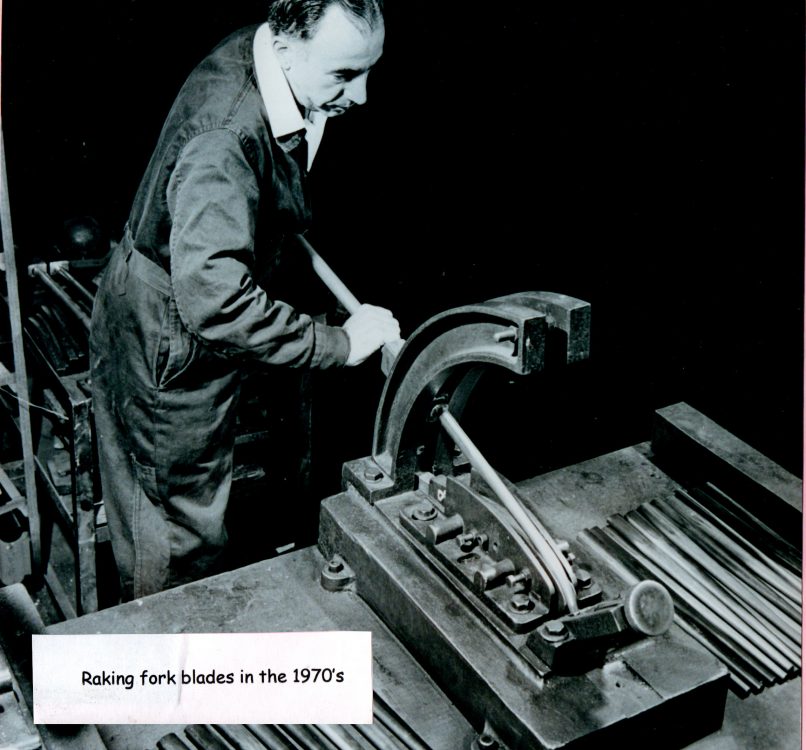

This period also saw major changes in the supply chain, especially the off-shoring from the UK, EU and USA for the higher volume bicycle frame manufacture into the Far East. The 1990s had also seen the move into aluminium framesets, and then carbon fibre frames which impacted on the ability of Reynolds to maintain a large UK factory, despite the knowledgeable staff and expertise in creating tubing to suit many types of frame design. In 2003, we set up a business relationship with Founder Land, based in Taichung, Taiwan so that we could still supply some Reynolds products locally to the large-scale steel frame builders who could fabricate frames locally for the brands we had worked with previously.

Reynolds had to reduce the size of our UK workforce in 2003, a very difficult time for the people involved but we retained the majority of employees and were able to continue UK manufacturing with a move from Hay Hall, Tyseley to our current Hall Green site in 2007, only a mile away in Birmingham. These changes meant we could make the lower volume but technically challenging 853, 631, 725 and titanium products in the UK and along with our Taiwan partners for chrome-moly tubing, move back into profitability again. We added the very high-strength stainless 953 to our range from 2006 and continued increasing the range of titanium, 853 and 631 parts as frame trends changed.

With a business that exported 75% of its’ UK-made product, the diverse nature of our customers in geography, frame design and applications proved to be a winning formula that weathered a number of recessions including after the global financial crash of 2008. Reynolds had adapted and become a niche business by 2010.

Reynolds has not launched any new materials during this time, a deliberate choice. Our 853 air-hardening steel was still outperforming competing steel alloys on the ever-tighter ISO frame testing requirements. Reynolds’ target for any replacement material must have at least 20% improvement in properties, along with being cost-competitive and usable by our customers, and it’s a testament to 853 that so far, we still cannot find a material that exceeds our benchmark in this area.

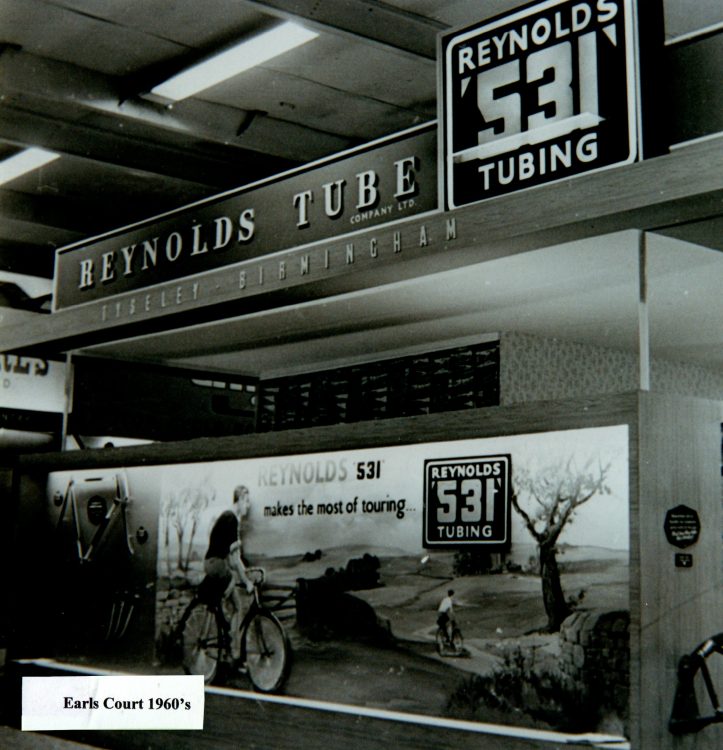

Like the 531 and 753 products which stayed in our range for several decades, our customers are investing in bikes that should stand the test of time and we aim to develop products that maintain this philosophy. We have indicated in a previous post why the 953 range is currently on hold, but the reason we selected that alloy remains relevant, although our 931 still is a very competitive choice for stainless frames.

In 2016, we started developing cycle parts using Additive Manufacturing (3D printing) in titanium, and have gradually learnt the pros and cons within this growing sector, applied to bike parts. A major opportunity that we continue to invest in, but practical issues like the cost, improved surface finishing and dimensional control remain on our development list as we increase our revenue in this sector, and support our many customers who will require access to this innovative technology.

Reynolds became an active member of the UK Niche Vehicle Network (NVN) and have provided steel and titanium tubing for lightweighting applications in a number of the automotive projects.

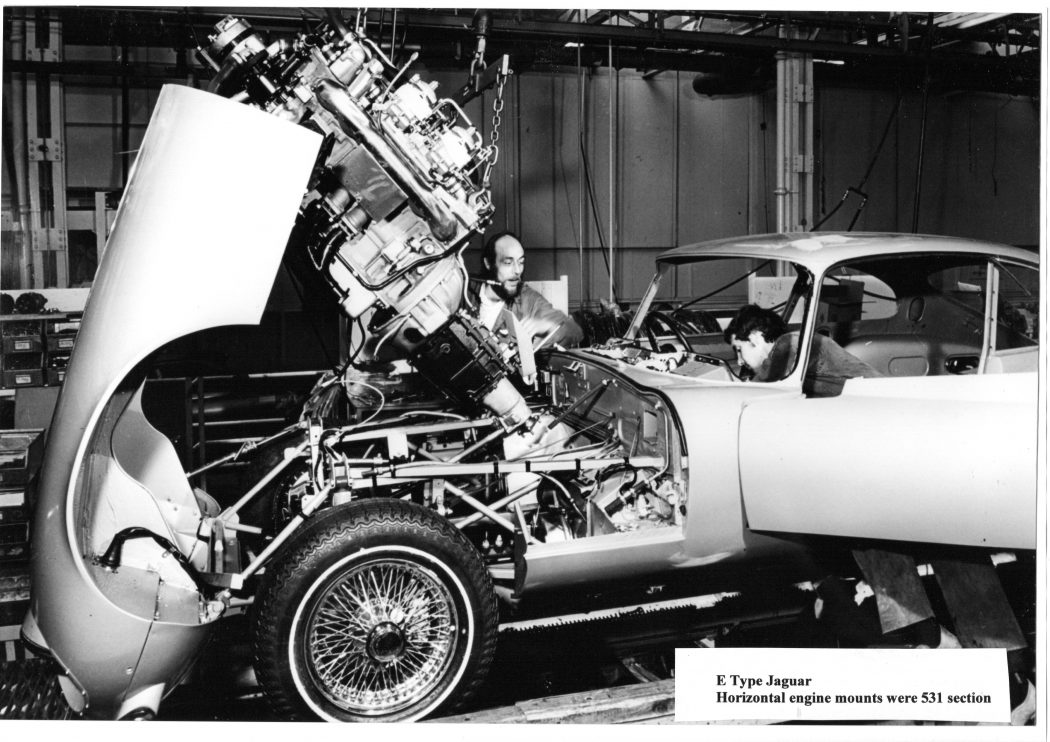

We still manufacture shaped tubing used in car chassis applications like the Jaguar D and E Type “retro” builds that originally used our 531 tubes. Project partnerships within the NVN also led to an increasing interest in electric motors and battery technology, which in turn led to the development of our lightweight e-bike drive system “Rey-Drive”, launched in June 2023 for use by custom-made bike frame builders.

We still have a number of customers who bought from us in 2000, like Independent Fabrications, Jamis, Mercian, Pashley, Raleigh, Rourke. But new names like Boettcher, Bixxis, Cotic, Enigma, Fairlight, Legend, Mason, Madison Genesis, Moots, Moulton, Norwid, Niner, Passoni, Temple, Stanforth, Starling have been added to our customer list.

In 2023, our key Trade shows were in Taipei and at Eurobike in Germany with custom-builder shows like MADE (US) and Bespoked (UK and Germany) being notable. We opened a Portuguese-based warehouse (Reynolds Technology Europe LDA), to supply custom builders within the EU trading zone. We are delighted to see the trend emerging towards sustainability, recycled content, lower CO2 and less plastic usage, and aim to do our part with changes to our production methods and travel.

In our 125th year, we remain a privately owned company, still re-invest all profits back into the business and can take a long-term view even in the tough economic climate that currently prevails within the cycling sector. A high proportion of our current staff from 1998 are still with us (including 2 with over 40 years’ service), the march of time means that we also have several who have or shortly will be retiring, but the recruitment and training for new employees has been a priority. We are currently trialling an extended 4-day production schedule at the factory so that our employees have a longer weekend break.

A big thanks to our loyal customers, suppliers and employees for their support and efforts especially over the last 25 years. It’s pretty normal in business to have a rollercoaster ride over decades, but some things change and others stay the same. Our task for the next 25 years is to continually innovate, adapt and survive!

On behalf of the entire Reynolds team, we wish you all a peaceful and relaxing holiday season and for good news into the New Year!

KN 20/12/2023.

Search

Categories

Archives

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- August 2023

- July 2023

- June 2023

- April 2023

- March 2023

- January 2023

- November 2022

- August 2022

- January 2022

- April 2021

- March 2021

- July 2019

- May 2019

- March 2019

- December 2018

- October 2018

- July 2018

- June 2018

- May 2018

- April 2018

- February 2018

- January 2018

- November 2017

- October 2017