Monday 20th November 2023

1936-1976: The Long-Standing History of 531 and 753

The Reynolds tubing company had been making straight gauge, constant wall thickness tubing for aircraft use from around 1916. After over 30 years of experience in the production of butted cycle tubing from mild steel, the technical staff had been actively developing high-strength steel alloy applications. This came from Reynolds’ involvement with the “aeronautics” requirements of that era and transferring that knowledge into the cycling sector. This is when Reynolds 531 and 753 were born.

The Launch of Reynolds 531

The combination of these factors resulted in the long-running success story of the 1935 launch of Reynolds 531:

- Butted tubing: To reduce the weight of a bike frame and place more metal where needed in the areas of highest stress.

- A new material: A manganese-molybdenum steel alloy to provide significantly higher strength and durability compared to mild steel, with a proven record of service in aircraft designs.

- Brand: The creation of the Reynolds 531 brand makes it a highly recognisable and sought-after tube set for high-performance bikes.

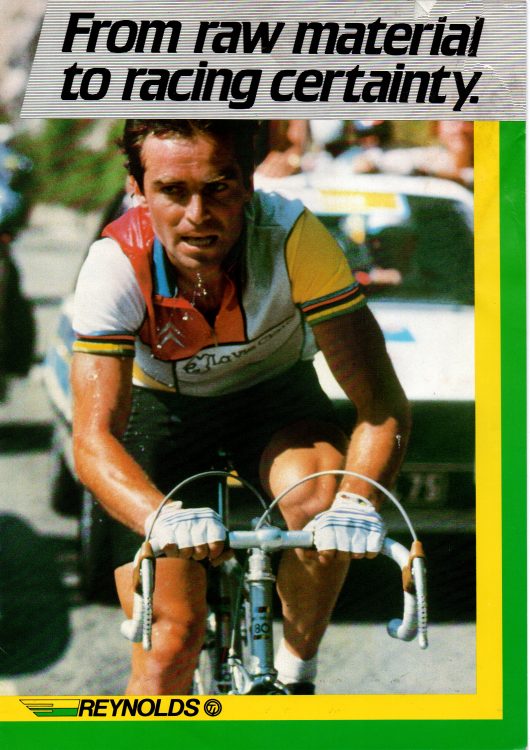

Enthusiasts helped keep the 531 tube sets at the forefront of cycle frame design into the late 1990s, including use by a wide range of cyclists from round-the-world touring to Tour De France wins with Charly Gaul, Eddy Merckx, Greg LeMond, and Miguel Indurain. There were several tube set variants for touring, and road racing like 531 Competition etc, because the frame designers would pick from varying diameters, wall thicknesses and shapes for their customers, all based on this alloy.

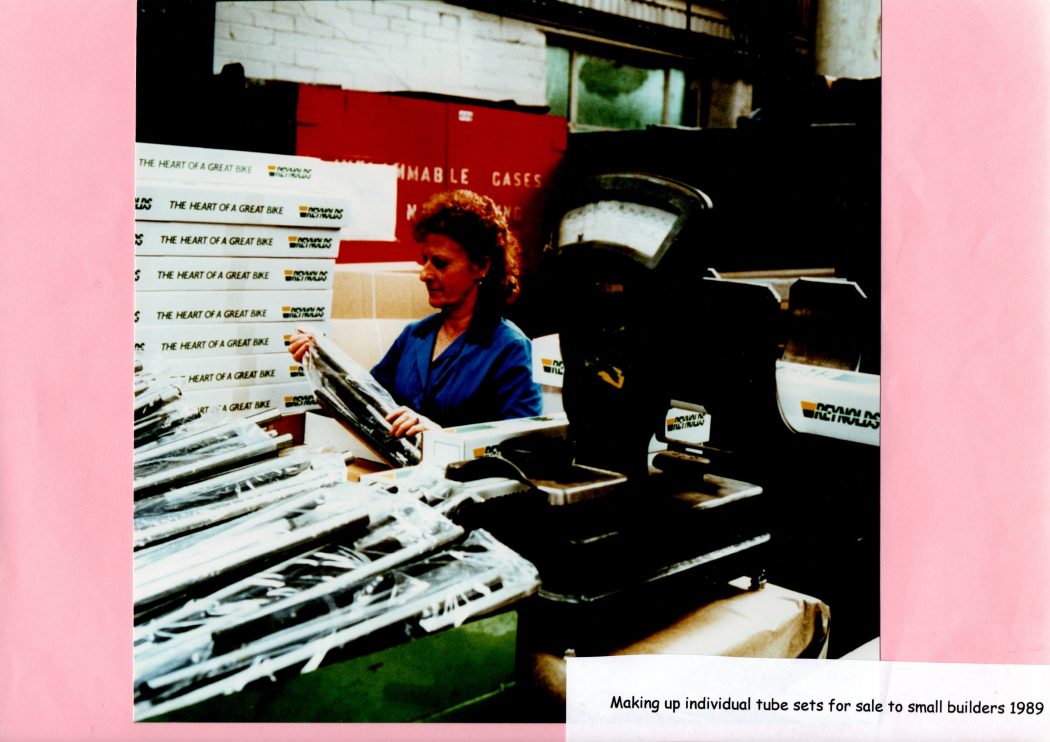

It is not easy to calculate how many tube sets were made during this period but it certainly exceeds 10 million sets made in the Tyseley, Birmingham factory. Many of these were exported worldwide. Among others, companies like Raleigh in the UK and Peugeot in France used 531 extensively for their top-end models and TDF replicas.

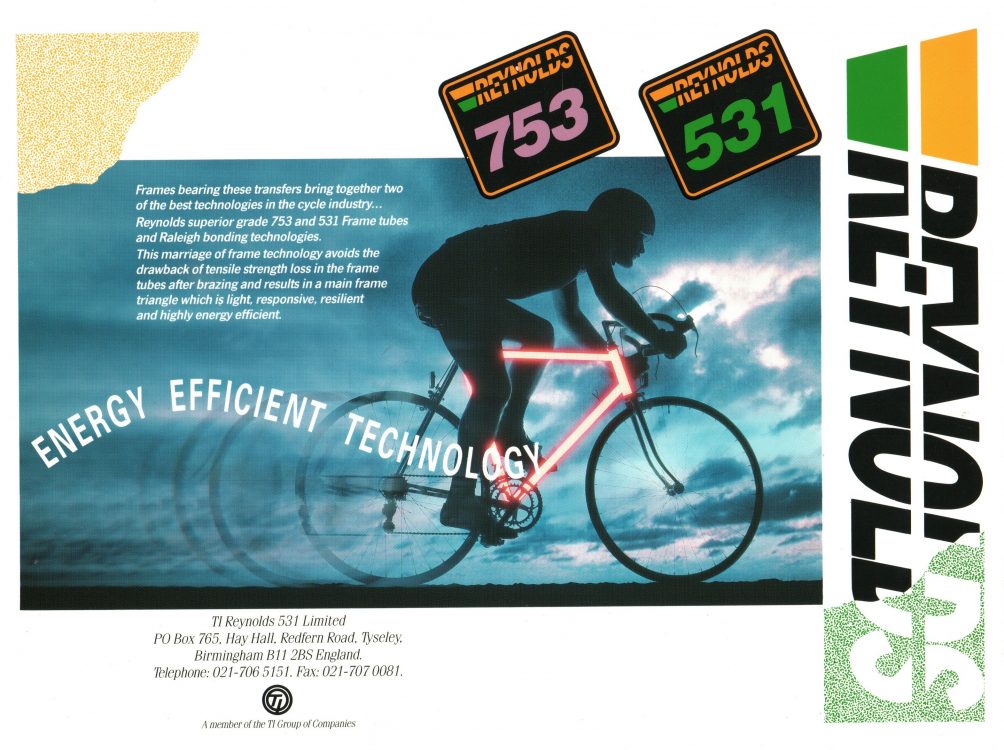

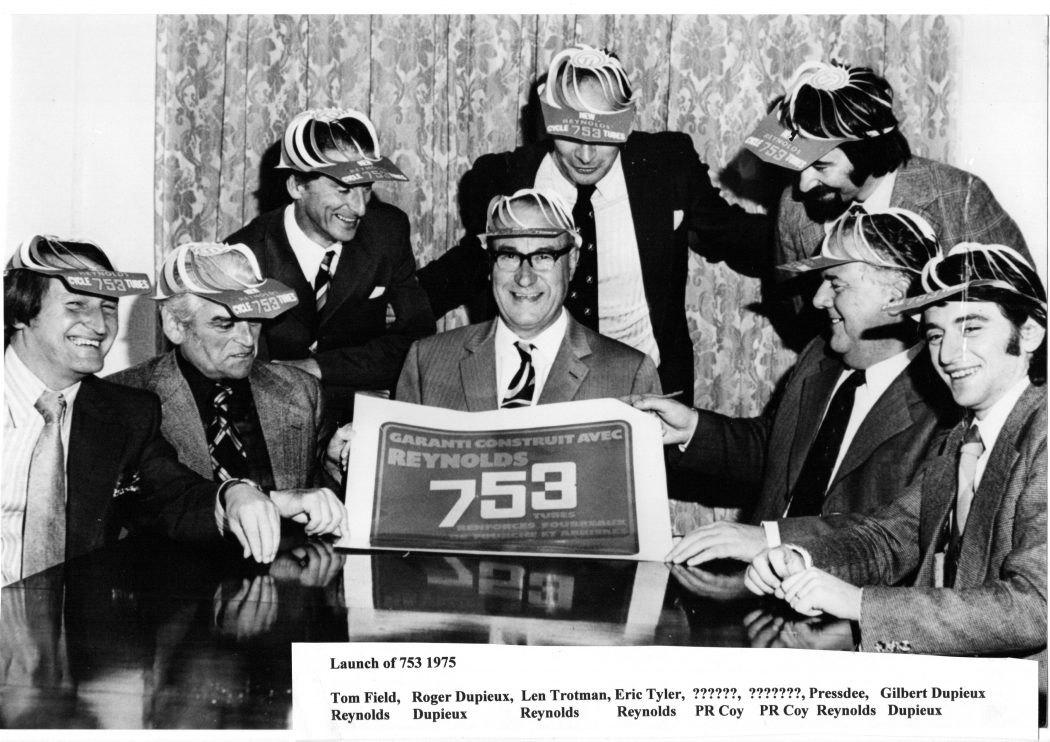

The Launch of Reynolds 753

Reynolds 753 was a further development using the 531 alloy. Launched in 1975, this was the first commercially available heat-treated tube set which allowed even lower weight framesets due to its higher strength. Because of the thin walls and innovative nature of this development, frame-builders had to be certified to use 753, based on a brazing sample that was submitted to Reynolds before each builder could purchase it for use on customers’ frames.

As frame fabrication methods changed from primarily brazed and/or lugged frames, the 531 and 753 manganese-molybdenum alloy gradually gave way in the late 1990s to the TIG weldable chrome-molybdenum alloys which Reynolds now uses under the brand names 525/520 and 725. We’d note the strengths of these modern alloys remain similar to 531 and 753 even now, which is a testament to the efforts of the Reynolds’ technical staff in the 1930s.

If you have a 531 or 753 frameset keep using it! In an age where disposable frames seem to have become more common, these frames are still very rideable. At every show we go to we meet riders who are still cranking out the miles on 531 framed bikes. The recent record is someone daily commuting on a 1950s Raleigh!

Search

Categories

Archives

- July 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- August 2023

- July 2023

- June 2023

- April 2023

- March 2023

- January 2023

- November 2022

- August 2022

- January 2022

- April 2021

- March 2021

- July 2019

- May 2019

- March 2019

- December 2018

- October 2018

- July 2018

- June 2018

- May 2018

- April 2018

- February 2018

- January 2018

- November 2017

- October 2017